Our bacteria is extremely efficient for a number of reasons. Largest consortium multi strain bacteria in the industry.

Dairy Effluent Ponds & Microbial Soil Inoculants

Parklink’s dairy effluent treatment products are designed to improve effluent management. With unparalleled capabilities to break down waste and improve effluent handling, these products reduce costs, increase operational efficiency and improve the value of your effluent as a fertiliser.

The unique consortium of microbes enhance the natural elemental cycles responsible for processing effluent. These products will improve effluent pumping, reduce odour and pond solids while improving the bio-availability of nutrients.

Quantum Soil & Plant Inoculant Products

The Quantum products consist of different combinations of naturally occurring microorganisms that share key traits for plant enhancement. The organisms inhabit the root zone and vascular system of a plant, helping to breakdown, hold and transport nutrients and water. Photosynthetic strains in the products are capable of converting radiant energy, including the sun’s, into energy for plant growth. Other organisms have the extraordinary ability to unlock chemical bonds, facilitating nutrient uptake that would not be available to the plant in the organism’s absence.

The Quantum products replace the natural soil microorganisms that are depleted through fumigation, tilling, harvesting and/or overuse of chemical controls. It is the only biological product on the market that is shelf stable AND contains photosynthetic and other vegetative cultures without the use of growth inhibitors. There is no other product available that meets these criteria.

Fluent®

Fluent®

Dairy Effluent Treatment

Fluent® contains specific facultative bacteria, along with a proprietary blend of bio stimulants to enhance the digestion process, reducing solids, odour and ammonia in stored waste.

– Reduced solids

– Reduced odours

– Reduced crust

– Easier pumping

– Increased pond capacity

– Effective growth across broad pH and temperature ranges.

– Simple to use and all-natural.

Packaging Sizes:

– 500g Water Soluble Packets (WSP)

– 10 kg Pail (20 x 500g WSP)

Dosing Instructions

Initial treatment:

- Calculate the volume of effluent in your pond: L x W x D = m³. Dose 2kg per 500m³ of pond volume.

Maintenance treatment:

- Dose 0.5kg (1 bag) per 100 cows. Add the maintenance dose on a monthly basis after the initial treatment.

Directions:

- If your pond has a crust, add the recommended amount of product into a bucket of water and mix thoroughly. Add solution directly into the drain that leads to the receiving pond. Be sure to wash the solution down with additional water.

- If your pond does not have a crust, you can simply throw the packs out onto the water where they will dissolve.

| Application | Schedule | Dose Rate |

| Initial Application |

First month | 2kg per 500m³ (pond volume) |

| Maintenance Application |

Once a month | 0.5kg per 100 cows |

Packaging Sizes:

– 500g Water Soluble Packs (WSP)

– 10 kg Pail (20 x 500g WSP)

What to Expect

– Increased bubbling within 7-10 days

– Reduced odours within 2-3 weeks

– The crust should start to get darker with time and should eventually disappear

– Reduced odour when irrigating

– Much easier to pump

– Reduced pasture regrowth times

Downloads

StreamGuard®

StreamGuard®

Reverse Nutrient Runoff

StreamGuard® pellets adsorb phosphorus and ammonia from water upon contact.

StreamGuard® pellets are made from naturally occurring and sustainable mineral materials. The pellets are non-hazardous, insoluble in water and non-toxic to aquatic plants and wildlife.

StreamGuard® can be implemented as a filter media to remove nutrients from a variety of flowing water sources such as streams, drains and channels.

StreamGuard® has high phosphate adsorption capacity (~ 81 mg/g), long service life, and once saturated, the pellets can potentially be recycled as a soil amendment.

StreamGuard® pellets can be packaged into a variety of vessels and chambers, as well as water permeable containers such as boom netting, gabions and filter baskets, depending on the application.

Click here for more info.

Downloads

Quantum-VSC®

Quantum-VSC®

Beneficial Soil and Plant Microbial Inoculant

A wide-ranging microbial consortium, which includes the core technology of both Quantum-Light and Quantum-HSC, along with additional spore-forming microbes selected for their ability to breakdown accumulated organics, such as thatch, black layer, and detritus. Through this breakdown process, the nutrients within the material are released and available for plant growth.

Product Specs

DESCRIPTION

Quantum-VSC is a plant and soil inoculant that restores and enhances the foundational levels of soil biology

(also known as the soil food web). This product incorporates heterotrophic bacteria into a diverse microbial

formulation that provides unprecedented plant enhancement at foliar, root and rhizosphere. The addition of

humate material to the formulation provides a readily usable carbon source.

PERFORMANCE CHARACTERISTICS

When used as a foliar or soil application, Quantum-VSC directly impacts plant vigor and performance by:

Improving nutrient uptake

Improving plant photosynthesis

Improving root and shoot growth

Fortifying plant natural defense systems

Promoting water production and retention

PRODUCT CHARACTERISTICS

Highly concentrated – Provides over 60 million colony forming units per milliliter.

Safe and easy to use – Non-toxic and contains non-pathogenic bacteria. It may be applied as a root drench or

as a foliar (diluted 10:1 with water) and is compatible with most types of irrigation systems to include: speed

sprayer, boom sprayer, pivot irrigation, aerial spray, micro-jet, etc.

No re-entry restrictions.

Easy storage – Does not require refrigeration.

Long life – Shelf stable for 3 years (unopened) and 1 year (opened).

Properties_______________________________________________________________________________

Guaranteed Bacterial Analysis: Rhodopseudomonas palustris 500,000 cfu/mL

Bacillus amyloliquefaciens 30,000,000 cfu/mL

Bacillus subtilis 15,000,000 cfu/mL

Bacillus licheniformis 750,000 cfu/mL

Bacillus megaterium 7,500,000 cfu/mL

Bacillus polymyxa 7,500,000 cfu/mL

Fertilizer Analysis: No NPK; fertilizer analysis of 0-0-0

pH: 6.5-8.0

Specific Gravity: 1.04 approximately

Particle Size: 100% through 100 micron/140 mesh

Appearance: Brown/Black liquid

Odor: Pungent and distinctive earthy odor

Packaging: Plastic 1 gallon bottles, 5 gallon totes, 30 gallon &

55 gallon drums and 275 gallon totes (mini-bulks)

Storage/handling: Shake/agitate before use. Re-cap as soon as

possible. Store between 32°F/0°C and 110°F/43°C.

Directions for use

Row Crops – 64 oz per acre at planting; 64 oz per acre at 14 to 21 days post planting; 64 oz per acre prior to

full canopy.

Grains (Irrigated) – 64 oz per acre at planting; 64 oz per acre at seed head development.

Grains (Non-irrigated) – 1 gallon per acre at planting.

Turf (Golf) – Initial application of 8 oz per 1,000 ft2 on tees and greens; 4 oz per 1,000 ft2 every 14 days.

Turf (Sod & Sport) – Initial application (including at planting) 1 gallon per acre; 64 oz every 30 to 45 days.

Vegetables (Greenhouse) – Water in seeds with 4 oz per gallon.

Vegetables (Outplanting) – Root dip or drench with 4 oz per gallon; 64 oz per acre every 14 to 21 days.

DO NOT MIX WITH FUNGICIDES OR PESTICIDES. When tank mixing, add the Quantum-VSC last and apply

within 0 to 12 hours.

For crop specific application rates and timing, visit www.GrowQuantum.com/product-application-rates.aspx.

Quantum Bacteria

AGRICULTURE PROBLEMS AND OUR SOLUTIONS.

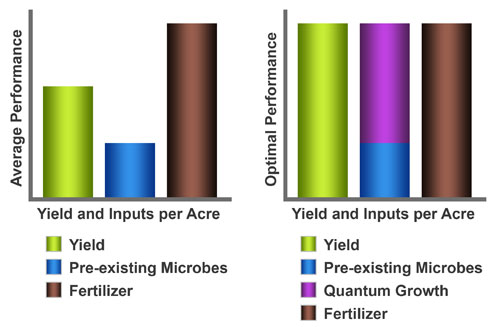

High input costs due to fertilizers not being utilized, nutrient run of, bio unavailability of nutrients, parasites and pests. Low returns due to low yields unhealthy plants, parasites and pests and bio inactive soil.

We solve these issues with 30-50% yield increases 50% decrease in fertilizer use and more resistance to parasites.

Two applications per growing season once with planting and once as a leaf spray will insure a active positive bio diversity in your soil.

Application can be done by irrigation systems or spraying by hand or tractor.

COMPLETELY LIVE CONSORTIUM WITH A VERY LONG SHELF LIFE.

Our bacteria is organic and natural, completely safe and pathogen free. It has a guaranteed shelf life of 3 years.

The nature of our consortium leads to an interesting phenomenon that is explained in its simplest form as self selection. Because we have such a wide range of bacteria functioning over different processes our bacteria flourishes in almost any environment.

The moment it is introduced into a system the availability of different types of waste will encourage the growth of the specific bacteria for that type of waste. This gives us the most successful bio augmentation product on the market today.

Why it works

| Genus(type) | What problems they solve: | |

| • | Nitrobacter | Nitrites |

| • | Nitrosomonas | Nitrogenous waste like, ammonia |

| • | Nitrococcus | Nitrites |

| • | Comamonas | Aromatic hydro carbons |

| • | Bacillus | Simple and aromatic hydrocarbons |

| • | Saccharomyces | Phosphorous, carbon, ammonia |

| • | Purple Sulfur bacteria | Sulphorous |

| • | Pseudomonas | Aromatic hydrocarbons |

| • | Alcaligenes | Nitrates |

| • | Citrobacter | Simple and aromatic hydrocarbons, nitrates |

| • | Flavobacterium | Simple hydro carbons |

| • | Purple Bacteria (non- sulphur) | Simple and aromatic hydrocarbons |

A RETURN TO NATURE.

While many in the agricultural industry, with the exception of organic farmers, readily accept the use of chemicals as a component of their cultural practices, the use of microbial products is less widely accepted and understood. Although the use of microorganisms as a way of enhancing plant development and productivity may be considered unusual or unnatural, it is actually one of the most natural approaches to realizing these benefits.

Our naturally occurring microbes work symbiotically with plants to enhance nutrient uptake, a key to plant health which provides plants additional energy for growth, defense and reproduction. Another advantage of microbial products is that applying too much has no adverse effects on the plant, soil, crop or environment as can happen with many chemicals.

THE QUANTUM GROWTH FACTS.

The Quantum Growth Series contains a unique, proprietary blend of naturally occurring vegetative and spore-forming microorganisms that is shelf-stable for three years and does not use growth inhibitors. When you use Quantum Growth products, you are restoring or dramatically increasing the populations of naturally occurring beneficial microorganisms in the soil.

The Quantum Growth Series is made of microorganisms or microorganisms combined with high quality peat humus extract. These products do not contain genetically modified organisms (GMOs) or traditional chemical fertilizers (NPK). The Quantum Growth Series is not compost tea, soil soup or manure tea. The series is the product of a complex, multi-stage fermentation process that takes place in the same container that reaches the grower. No dilution takes place during the production of the products.

FAQ

Why use the Quantum Growth® Series of products?

The Quantum Growth Series of products replace the natural soil microorganisms that are depleted through fumigation, tilling, harvesting, and/or overuse of chemical controls. If your business is maximising plant yield or turf performance and you do so by augmenting crops or turf with fertiliser and micronutrients, it only makes sense that you increase the microorganisms that process the nutrients for the plant. When you use our products, you are restoring or dramatically increasing the populations of naturally occurring beneficial microorganisms in the soil, resulting in optimal crop yield or turf performance.

How is the Quantum Growth Series different from other biological products?

The Quantum Growth Series of products are the only biological products that are shelf-stable, contain photosynthetic and other vegetative cultures, and do not use growth inhibitors. There is no other product that meets these criteria.

What Quality assurances can you provide?

The Quantum Growth Series of products are manufactured in an EPA- and FDA- registered facility. Each container of a Quantum Growth product goes through a multi-stage fermentation process in its own container, and is not diluted during fermentation. The Quantum Growth Series is not a compost tea, manure tea, soil soup, or any other product of an uncontrolled process. The Quantum Growth Series is biotechnology and biophysics in a bottle.

Do your products contain genetically modified organisms?

No. The Quantum Growth Series is composed of microorganisms or microorganisms combined with high quality peat humus extract, depending on the specific product. Quantum Growth contains no genetically modified organisms.

Are the Quantum Growth products shelf-stable?

Yes, they are. Long-term shelf stability of the Quantum Growth photosynthetic cultures is a significant advancement in microbiology, an achievement that we’re most proud of. In addition, the microorganism base features significantly elevated levels of activity shortly after application, boosting its already potent effect.

Downloads

Quantum-Total®

Quantum-Total®

Beneficial Soil and Plant Microbial Inoculant

A next generation biological formulation that combines the photosynthetic technology of Quantum-Light with other PGPR (plant growth promoting rhizobacteria) strains. This dynamic combination of cultures enhances plant photosynthesis, improves mineral availability and fortifies plant natural defence systems. May be applied as a soil drench or as a foliar.

Product Specs

DESCRIPTION

Quantum-Total is a plant and soil inoculant that restores and enhances the foundational levels of soil biology

(also known as the soil food web). This product incorporates highly specialized photosynthetic and

heterotrophic bacteria into a diverse microbial formulation that provides unprecedented plant enhancement at

foliar, root and rhizosphere.

PERFORMANCE CHARACTERISTICS

When used as a foliar or soil application, Quantum-Total directly impacts plant vigor and performance by:

Improving nutrient uptake

Improving plant photosynthesis

Improving root and shoot growth

Fortifying plant natural defense systems

Promoting water production and retention

PRODUCT CHARACTERISTICS

Highly concentrated – Provides over fifty million colony forming units per milliliter.

Safe and easy to use – Non-toxic and contains non-pathogenic bacteria. It may be applied as a foliar or root

drench and is compatible with most types of irrigation systems to include: speed sprayer, boom sprayer, pivot

irrigation, aerial spray, micro-jet, etc.

No re-entry restrictions.

Easy storage – Does not require refrigeration.

Long life – Shelf stable for 3 years (unopened) and 1 year (opened).

Properties_______________________________________________________________________________

Guaranteed Bacterial Analysis: Rhodopseudomonas palustris 900,000 cfu/mL

Bacillus amyloliquefaciens 20,000,000 cfu/mL

Bacillus subtilis 10,000,000 cfu/mL

Bacillus licheniformis 10,000,000 cfu/mL

Bacillus megaterium 5,000,000 cfu/mL

Bacillus polymyxa 5,000,000 cfu/mL

Fertilizer Analysis: No NPK; fertilizer analysis of 0-0-0

pH: 6.9-8.0

Specific Gravity: 0.9958

Particle Size: 100% through 100 micron/140 mesh

Appearance: Brown to black liquid

Odor: Pungent and distinctive earthy odor

Packaging: Plastic 1 gallon bottles, 5 gallon totes, 30 gallon &

55 gallon drums and 275 gallon totes (mini-bulks)

Storage/handling: Shake/agitate before use. Re-cap as soon as

possible. Store between 32°F/0°C and 110°F/43°C.

Directions for use

Row Crops – 64 oz per acre at planting; 64 oz per acre at 14 to 21 days post planting; 64 oz per acre prior to

full canopy.

Grains (Irrigated) – 64 oz per acre at planting; 64 oz per acre at seed head development.

Grains (Non-irrigated) – 1 gallon per acre at planting.

Turf (Golf) – Initial application of 8 oz per 1,000 ft2 on tees and greens; 4 oz per 1,000 ft2 every 14 days.

Turf (Sod & Sport) – Initial application (including at planting) 1 gallon per acre; 64 oz every 30 to 45 days.

Vegetables (Greenhouse) – Water in seeds with 4 oz per gallon.

Vegetables (Outplanting) – Root dip or drench with 4 oz per gallon; 64 oz per acre every 14 to 21 days.

Citrus (fair to good condition):

1 gallon Pre-bloom or early bloom

Full bloom or 2/3 petal fall

With summer spray*

With fall spray*

6 to 8 weeks prior to harvest

Citrus (poor condition):

1 gallon As a foliar* or through ground irrigation every 30 days

Optional Foliar Spray Program:

2 gallons Feb/Mar

Jun/Jul

Sept/Oct

Nov

6 to 8 weeks prior to harvest

New Plantings/Resets:

2 oz per tree At transplant with watering in solution

* if spray includes and form of a pesticide, apply Quantum Growth through injection into ground irrigation

system

DO NOT MIX WITH FUNGICIDES OR PESTICIDES. When tank mixing, add the Quantum-Total last and apply

within 0 to 12 hours.

For crop specific application rates and timing, visit www.GrowQuantum.com/product-application-rates.aspx

Quantum Bacteria

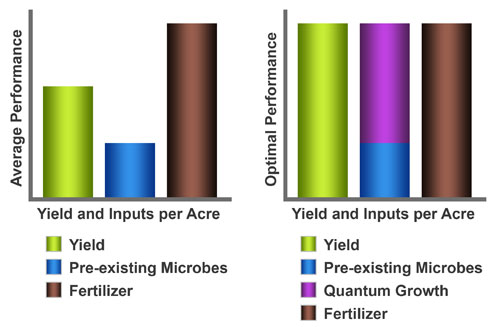

AGRICULTURE PROBLEMS AND OUR SOLUTIONS.

High input costs due to fertilizers not being utilized, nutrient run of, bio unavailability of nutrients, parasites and pests. Low returns due to low yields unhealthy plants, parasites and pests and bio inactive soil.

We solve these issues with 30-50% yield increases 50% decrease in fertilizer use and more resistance to parasites.

Two applications per growing season once with planting and once as a leaf spray will insure a active positive bio diversity in your soil.

Application can be done by irrigation systems or spraying by hand or tractor.

COMPLETELY LIVE CONSORTIUM WITH A VERY LONG SHELF LIFE.

Our bacteria is organic and natural, completely safe and pathogen free. It has a guaranteed shelf life of 3 years.

The nature of our consortium leads to an interesting phenomenon that is explained in its simplest form as self selection. Because we have such a wide range of bacteria functioning over different processes our bacteria flourishes in almost any environment.

The moment it is introduced into a system the availability of different types of waste will encourage the growth of the specific bacteria for that type of waste. This gives us the most successful bio augmentation product on the market today.

Why it works

Our bacteria is extremely efficient for a number of reasons. Largest consortium multi strain bacteria in the industry.

| Genus(type) | What problems they solve: | |

| • | Nitrobacter | Nitrites |

| • | Nitrosomonas | Nitrogenous waste like, ammonia |

| • | Nitrococcus | Nitrites |

| • | Comamonas | Aromatic hydro carbons |

| • | Bacillus | Simple and aromatic hydrocarbons |

| • | Saccharomyces | Phosphorous, carbon, ammonia |

| • | Purple Sulfur bacteria | Sulphorous |

| • | Pseudomonas | Aromatic hydrocarbons |

| • | Alcaligenes | Nitrates |

| • | Citrobacter | Simple and aromatic hydrocarbons, nitrates |

| • | Flavobacterium | Simple hydro carbons |

| • | Purple Bacteria (non- sulphur) | Simple and aromatic hydrocarbons |

A RETURN TO NATURE.

While many in the agricultural industry, with the exception of organic farmers, readily accept the use of chemicals as a component of their cultural practices, the use of microbial products is less widely accepted and understood. Although the use of microorganisms as a way of enhancing plant development and productivity may be considered unusual or unnatural, it is actually one of the most natural approaches to realizing these benefits.

Our naturally occurring microbes work symbiotically with plants to enhance nutrient uptake, a key to plant health which provides plants additional energy for growth, defense and reproduction. Another advantage of microbial products is that applying too much has no adverse effects on the plant, soil, crop or environment as can happen with many chemicals.

THE QUANTUM GROWTH FACTS.

The Quantum Growth Series contains a unique, proprietary blend of naturally occurring vegetative and spore-forming microorganisms that is shelf-stable for three years and does not use growth inhibitors. When you use Quantum Growth products, you are restoring or dramatically increasing the populations of naturally occurring beneficial microorganisms in the soil.

The Quantum Growth Series is made of microorganisms or microorganisms combined with high quality peat humus extract. These products do not contain genetically modified organisms (GMOs) or traditional chemical fertilizers (NPK). The Quantum Growth Series is not compost tea, soil soup or manure tea. The series is the product of a complex, multi-stage fermentation process that takes place in the same container that reaches the grower. No dilution takes place during the production of the products.

FAQ

Why use the Quantum Growth® Series of products?

The Quantum Growth Series of products replace the natural soil microorganisms that are depleted through fumigation, tilling, harvesting, and/or overuse of chemical controls. If your business is maximising plant yield or turf performance and you do so by augmenting crops or turf with fertiliser and micronutrients, it only makes sense that you increase the microorganisms that process the nutrients for the plant. When you use our products, you are restoring or dramatically increasing the populations of naturally occurring beneficial microorganisms in the soil, resulting in optimal crop yield or turf performance.

How is the Quantum Growth Series different from other biological products?

The Quantum Growth Series of products are the only biological products that are shelf-stable, contain photosynthetic and other vegetative cultures, and do not use growth inhibitors. There is no other product that meets these criteria.

What Quality assurances can you provide?

The Quantum Growth Series of products are manufactured in an EPA- and FDA- registered facility. Each container of a Quantum Growth product goes through a multi-stage fermentation process in its own container, and is not diluted during fermentation. The Quantum Growth Series is not a compost tea, manure tea, soil soup, or any other product of an uncontrolled process. The Quantum Growth Series is biotechnology and biophysics in a bottle.

Do your products contain genetically modified organisms?

No. The Quantum Growth Series is composed of microorganisms or microorganisms combined with high quality peat humus extract, depending on the specific product. Quantum Growth contains no genetically modified organisms.

Are the Quantum Growth products shelf-stable?

Yes, they are. Long-term shelf stability of the Quantum Growth photosynthetic cultures is a significant advancement in microbiology, an achievement that we’re most proud of. In addition, the microorganism base features significantly elevated levels of activity shortly after application, boosting its already potent effect.